3D Plant Design & Equipment Engineering Software – CADISON

CADISON® Technology

Modular Plant Design and Object-Oriented Software for Plant Design

- ITandFactory GmbH (a subsidiary of Neilsoft Group) has been developing process industry solutions from last two decades based on object oriented technology with a mission of improving engineering efficiency and focusing more on project workflow challenges such as real integration, change management, centralized documentation, real-time updates, unification of data graphics (instead of just managing information with high end database solutions).

- It has developed a consistent system of data management which increases flexibility of the overall process and enables parallel collaboration - which improves division of labour (remote teams), accuracy, speed and project success.

- CADISON solution is built around the object oriented technology with modular architecture enabling a model-based process for ‘intelligent & integrated plant information modeling’.

- It provides the flexibility to customize Workflows, Object Models & Catalogs to one’s own company standards and automatically generate Reports, BOM, MTOs, Isometrics & 2D GA drawings to improve project execution efficiency. It also has built-in revision control & project co-ordination capabilities.

- CADISON® integrates into the Autodesk environment by using the graphics engine of AutoCAD® and has built-in calculations, interfaces to ERP and pipe stress calculation tools making it a complete engineering system.

- Backed by project engineering services from its parent company Neilsoft Ltd.(a global group of more than 1000 person), we ensure smooth implementation and successful execution of projects in CADISON® making us a complete solution provider.

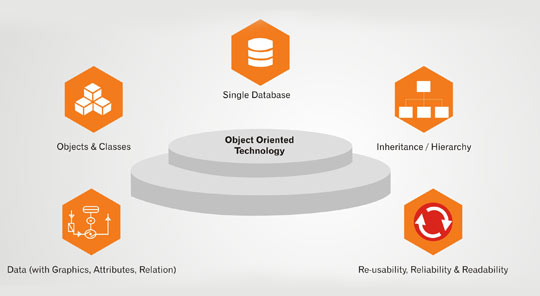

Object Oriented Technology

- CADISON uses Object Oriented Technology at its core unlike other tools for efficient plant engineering. It not only store / retrieve object data with all attributes in a structured manner but also maintains all the relationships/inheritance of multi-disciplinary objects and object classes being added.

- One common storage system (single object for graphic and engineering data) helps every project team member to work together in just one working environment simultaneously, delivering the latest updated information of the projects in all views across all disciplines in real time.

- This technology improves engineering efficiency by reducing data redundancy, maintaining up-to-date data for all users, real time integration & communication between different disciplines and automatic report generation at project level.

- It is possible to standardize, reuse and even reconfigure relationships between objects as well as placement of objects.

Advantages:

- Data is stored as objects and object classes and not just entity (as in other tools)

- Objects consists of not only attributes but also inheritance/hierarchy attached with it unlike other database solution

- Built-in PDM for document management, no need of separate document management system and added IT infrastructure & administration cost

- No data redundancy and duplication. Reuse of objects across projects enables engineers to build and reuse models quickly as well as leverage the department’s accumulated knowledge base

- Lowest Project Set-up time with quick Logical project structuring (relationships/hierarchies)

- Flexibility of object level customization (at user level) as per company standards, no programming/development required (as in other tools)

Modular Architecture for Real Integration

- CADISON has one of the best modular architecture with embedded integration & connectivity between the different disciplines and unifying the entire engineering workflow in one system.

- Being an integrated system, user can start the project with any specific module/discipline (for e.g. P&ID designer) and extend it to multiple disciplines by activating/adding required module based on the needs of the project.

- This modular approach helps to optimize initial investment and realize ROI over the project life-cycle. It also provides flexibility to the users to customize workflows, object models & catalogs to one’s own company standards.

- Improved workflow eliminates the need to split up tasks into different models because the 3D model allows for better coordination of documentation, allowing for concurrent modeling, analysis and design.

- For example, a pump as an object can be specified by project engineer using a non-cad tool (project engineer) or can be selected from a catalog manager (Matpipe) into a P&ID diagram by Process engineer.

- It will have all engineering data and graphics (schematics & 3D) with associated components attached to it such as motor, instrumentation, etc. This helps electrical department to create circuit diagrams easily using electrical designer and piping engineers in 3D model using 3D designer.

- Being an integrated system, any change in one component will update all representations and associated data behind it across all disciplines thereby achieving real integration and effective change management.

Advantages:

- Integration of entire engineering process for efficient planning across the project life-cycle from quotation to maintenance

- Unique Architecture and Single Object-Oriented Database eliminates the need to frequently synchronize and update between different disciplines & databases

- Avoids many interfaces and transmission errors to work seamlessly between different disciplines

- Effective change management/revision management with real-time updates

- Easy integration into the business workflow of your company (ERP, document management, stress calculation, visualization, etc.)

Model based Process (i2 PIM): The BIM philosophy for plant engineering

- In order to address real plant engineering challenges you need a solution which is intelligent, integrated, reactive and modular. Either you invest in a very high end (expensive) tools & IT infrastructure or follow a process which helps to achieve it in a very cost effective manner.

- With its built-in technology and modular architecture, CADISON enables an intelligent model-based process for planning, design, construction and management of plant & plant equipment. It is an ‘intelligent and integrated Plant Information Modeling’ (i2 PIM) which makes BIM implementation more plant specific.

- i2 PIM uses objects systematically in a single, centralized database where design data is stored in a structured way as ‘intelligent objects’ filled with information, hierarchy and properties that can be shared and worked on collaboratively by all disciplines across a single object model.

i2 PIM Model Based Process = Create/add intelligent objects + Store the objects in a structured manner (Project Structuring) + Collaboration (through single database)

- Built-in Structured Cost Estimator (in the Project Engineer module) which is linked to the objects and operates in a tree structure helps to calculate costs at project level and sub-project level (by discipline or by sub-system or as desired by the project manager based on structuring). It is also possible to directly generate cost reports and proposals from the CADISON system which is a big time - saver

- Since Proposal structure(information) is brought forward in the basic engineering stage, i2 PIM process minimizes incorrect interpretations about design intent, which can lead to delayed schedules, change orders, and RFIs after construction begins

- Information generated at P&ID stage (in P&ID Designer) is available during electrical design, instrumentation and 3D Piping/Isometric for generating documentation/reports

- During design development i2 PIM enables customization of workflows, object models and catalogs to conform to organization standards

- i2 PIM brings in intelligence in the system by reducing manual work for Tagging/Labeling by using information from objects. User can also switch from different Tagging systems (DIN/KKS) and the changes made are automatically updated in the reports

- i2 PIM helps in streamlining unified workflow that manages detailed modeling, change management, collaboration between disciplines, integration with 3rd party applications, quality assurance and revision control/management

- With i2 PIM, design and construction documents are dynamically linked, the amount of time to evaluate alternatives, execute design changes, and produce construction documentation is reduced significantly.

Advantages:

- Work completed at any stage of the project lifecycle can be applied to future stages, creating additional efficiencies and freeing up staff time for more strategic work.

- Organizations that use i2 PIM processes are transforming how they engineer plants, utilities and plant equipment, resulting in a workflow advantage, competitive advantage and shortened project cycles.

- i2 PIM processes helps in 50+% improvements in plant engineering efficiencies, 30+% cost reductions and 90+% reductions in documentation efforts compared to AutoCAD

Comprehensive Solution with built-in (design, calculation, Analysis, etc.) capabilities

- CADISON is a comprehensive Engineering Solution right from project planning to designing of process plants and process equipments. Our solution has expanded to reflect the needs of various stakeholders.

- We have everything you need in one place and our mission is to reduce the money and time your business spends procuring various (plant) design tools and improving your project engineering efficiency by up to 30%.

- CADISON provides the complete engineering environment for various phases of plant design. The Process and project engineer(s) does project planning, structuring of plants and detailing of technical and commercial data using a cost estimator - PROJECT ENGINEER.

- Proposals are more easily understood by all users as well as customer due to accurate visualization. P&ID planning engineers uses CADISON P&ID Designer for basic engineering for preparation of block flow diagrams and P&ID’s.

- CADISON enables Pipeline Sizing and Utility Pump Sizing calculations for optimum selection of equipments at P&ID stage. Installation and piping engineers use CADISON 3D Designer for accurate 3D space planning and generations of 2D layouts (GA drawing, Isometrics) for construction.

- Flexibility to develop and add vendor specific equipment models (catalogs), pipe classes through built-in MATPIPE for creation of project and company standards.

- Its user friendly wizards (Steel Layout, Pipe Support Modeller) , CAD interfaces [such as Inventor (*.SAT), native AutoCAD (*.DWG.), or Solidworks along with stress analysis (CAESER II, ROHR II) tools]and built-in Report Generator for building engineering data with clash free 3D models leads to efficient detailed engineering.

- Electrical and Instrumentation engineers develop complete schematics, circuit diagram, cable routing including sizing calculations (Cable, Transformer, Earthing and Battery sizing) using CADISON Electrical Designer.

- Project manager and Project Operator can view entire project data /documentation with CADISON Project Navigator or Engineer2Web.

- Integration of the engineering workflow with the enterprise is possible with CADISON API, add-on modules for design reviews and visualization (Navisworks Manage), ERP integration, etc. makes CADISON a complete system.

Advantages:

- CADISON built-in technology, breadth of product portfolio, depth of our in-house expertise and support helps in keeping the total cost of adoption/ownership low and gives more value for your money (ROI)

- Improves overall business efficiency by more than 30%

- Cost Estimator

- Basic Engineering (PFD/P&ID’s)

- Engineering Calculations

- Catalog Manager

- 3D Design & Layouts

- Electrical Design

- Reports

- Construction drawings

- Enterprise Resource Planning (ERP)

Modules

CADISON Project Engineer is a tool for project planning, structuring of plants and detailing of technical and commercial data using a cost estimator. User may create plant work breakdown structure and calculate cost in a non-graphical environment.

CADISON Project Engineer

CADISON Piping and instrumentation design software - P&ID Designer is an comprehensive solution for creation of PFD/P&ID, Instrumentation (measurements, hook-up’s, I/O‘s), specifications and calculations (media, pipe specification, pipe sizing, etc.) and report generation.

CADISON P&ID Designer

CADISON 3D Designer is a complete plant design suite with 3D modeling features which allows the users to build plant layouts, pipeline routing, HVAC duct routing, equipment modeling, steel layouts, Isometric drawing creation and report generation.

CADISON 3D Designer

CADISON MATPIPE is an independent module for development and management of pipe classes, creation of parameterized 3D components, preparation and integration of manufacturer catalogues, import and export of data plus examination of existing catalogue data to ensure up-to-date data is available in the system

CADISON MATPIPE

CADISON Electrical Designer is a comprehensive solution for schematic & controls design, sizing calculations, 3D cable tray & panel layouts, automatic report generation, bill of materials (BOM), material take-offs & lists.

CADISON Electrical Desinger

CADISON STEEL Layout is a comprehensive tool for planning and creating 3D steel structures efficiently in plant design. Steel Layout has wizards for creation of Ladders, Staircases, Platform, Rails and Water tanks efficiently and error free.

CADISON Steel Layout

CADISON Pipe Support Modeler assists a user to create and edit the secondary supports in an easy and intelligent manner. The wizard for pipe support allows a user to create different types of predefined supports.

CADISON Pipe Support Modeler

CADISON Project Navigator is a pure ‘viewing Tool’ for your access to all engineering data of your projects. The navigator has been designed for staff members normally not involved in the active planning of a plant but afterwards responsible for operation and maintenance of the plant (i.e. mere data consumers).

CADISON Project Navigator

The CADISON Archiver allows you to swap and archive complete projects from the CADISON productive environment. Archived projects can be rapidly and easily viewed with the CADISON Archive-Browser without the need to retrieve them from the productive environment.

CADISON Archiver

Interface

The CADISON Inventor interface enables users to import an Autodesk Inventor part or assembly into CADISON environment as a CADISON object. Add-on menu in Inventor will assist users in exporting Inventor part or assembly file into SAT and XML format.

CADISON Inventor Interface

CADISON provides interfaces with industry standard CAE software’s – CAESER II & ROHR II for quick and accurate analysis of piping system subjected to wide variety of loads taking in to account weight, pressure, thermal, seismic and other static and dynamic conditions based on user defined variables and accepted industry guidelines.

CADISON CAESAR II Interface

CADISON ROHR II for quick and accurate analysis of piping system subjected to wide variety of loads taking in to account weight, pressure, thermal, seismic

CADISON ROHR2-Interface

The bidirectional CADISON ERP interface combines the ERP and engineering workflow for creation of a highly integrated system. For instance, orders can be directly released and controlled from the engineering workflow.

CADISON ERP-Interface

The CADISON API allows you to optionally integrate your CADISON engineering workflow in your business workflow.

CADISON Application Programming Interface